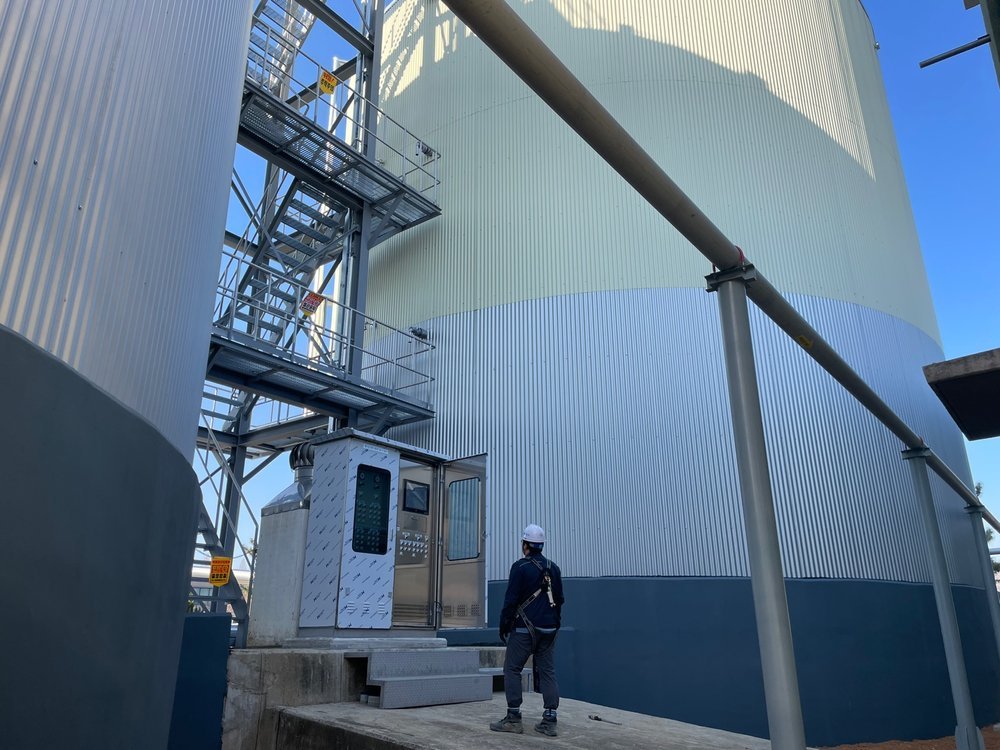

Advanced Anaerobic Digestion (AAD)

Biogas plant with high-efficiency mixing technology

Achieving Full Mixing - No Dead Space

Improve digestion efficiency with a mixer capable of moving up and down / left and right (10° ~ 350°).

Suppression of upper scum and prevention of lower sediment sedimentation by preventing the occurrence of dead space in the digester

Mixing efficiency verified by computational fluid dynamics (CFD) analysis

Determination of mixer specifications / no. of units considering inlet solid concentration and digester capacity / shape

Easy to attach and detach during installation and maintenance, enabling easy and efficient maintenance

- An established technology to decompose organic matter into methane and carbon dioxide through different steps of hydrolysis, acid fermentation, and methane fermentation in oxygen-free environment

C6H12O6 → 3CH4 + 3CO2- Energy input is low because there is no oxygen supply, and sludge generation is low because anaerobic microorganisms with a slow growth rate are used

- AD is implemented for organic waste volume reduction and renewable energy production facilities

Additional Value from Organic Wastes

•Renewable energy(biogas) production by AD / various application of the biogas

•Producing high value materials from the organic wastes

•Contribution to carbon neutrality by utilizing biogas

Applications

Solubilization of Sludge

For increased production of biogas: more than 120% increase in biogas production (compared to non-solubilization) / 30% reduction in residence time in anaerobic digester

Organic Waste to Energy

Simultaneous solubilization and reduction achieved. Biogas production increase of 140% or more (compared to non-solubilization) / sludge reduction rate of 90% achieved.

Energy Production Process

For energy self-sufficiency in sewage treatment plant.

Miryang City Livestock Excrement Public Treatment Facility

Electricity Cost 122M KRW/y SAVED

CO2 Emission 6,200t/y Reduced

Facility capacity: Total 100 tons/day (livestock manure 80 tons/day, food 20 tons/day)

Methane production rate: 0.40 Nm³ CH₄/kgVS (design)

Organic matter removal rate: 70.0% (design)

The AAD Advantage

Consistent Efficiency

Sediment deposition is sent through an agitator capable of up and down/left and right flow.

Stable Biogas Production

Even when the inflow TS is 8% or more our technology can output consistent levels of biogas.

Convenient Operation

Equipped with an automatic control system linked with digester and measurement equipment.

Reduce OPEX

With maximized efficiency, less energy usage and less maintanance

Featured AAD References

Miryang City Livestock Excrement Public Treatment Facility

- Facility capacity: Total 100 tons/day (livestock manure 80 tons/day, food 20 tons/day)

- Methane production rate: 0.40 Nm³ CH₄/kgVS (design)

- Organic matter removal rate: 70.0% (design)

Daegu City Organic waste resources integrated energy facility

- Facility capacity: Total 20 tons/day (food 18 tons/day sewage sludge 2 tons/day)

- Methane production rate: 0.51 Nm³ CH₄/kgVS (130% compared to design)

- Organic matter removal rate: 86.8%

Daejeon Sewage Treatment Plant Modernization Project (under design)

- Facility capacity: Total 727 tons/day (sewage sludge 727 tons/day)

- Methane production rate: 0.25 Nm³ CH₄/kgVS (design)

- Organic matter removal rate: 55.0% (design)

Hongcheon Green Energy Town

- Facility capacity: Total 100 tons/day (livestock manure 80 tons/day, food waste 20 tons/day)

AAD References

| Year | Name | Location | Capacity | Comments |

| 2015 | Hongcheon Green Energy Town | Hongcheon, Korea | 100 tons/day (Livestock Manure 80 + Food Waste 20) | Operating AAD (Mesophilic 2 Digesters) |

| 2021-2022 | Organic Waste Resource Integrated Energy Demonstration Facility | Daegu City, Korea | 20 ㎥/day (Food Waste 18 + Sewage Sludge 2) | National Research Program Completed AAD + AMX |

| 2022 | Miryang Public Livestock Manure Treatment Plant | Miryang City, Korea | 100 ㎥/day (Livestock Manure 80 + Food Waste 20) | Operating AAD (Mesophilic 2 Digesters) |

| 2023 | Livestock Manure Public Treatment Facility | Gimhae City, Korea | 200 ㎥/day (Livestock Manure 150 + Food Waste 50) | Currently Seeding + Startup AAD (Mesophilic 3 Digesters) |

| 2026 (Expected) | Hwacheon Public Livestock Manure Treatment Plant | Hwacheon-gun, Gangwon-do, Korea | 90 ㎥/day (Livestock Manure 73 + Food Waste 17) | Under Construction AAD (Mesophilic 2 Digesters) |

| 2026 (Expected) | Muan Public Food Waste Treatment Plant | Muan-gun, Korea | 40 ㎥/day (Food Waste) | In Design AAD + AMX |

| 2027 (Expected) | Seongju Integrated Bio-energy Plant | Seongu-gun, Gyeongsangbuk-do, Korea | 150 ㎥/day (Livestock Manure 116 + Food Waste 12 + Dewatered Sewage Sludge 7 + Agricultural Residues 15 | In Design AAD (Mesophilic 2 Digesters) |

| 2028 (Expected) | Daejeon Sewage Treatment Plant Modernization Project | Daejeon City, Korea | 840 ㎥/day (Municipal WWTP Sludge) | Under Construction Draco THP + AAD + AMX |