AAD

Advanced Anaerobic Digestion

AAD

Advanced Anaerobic Digestion

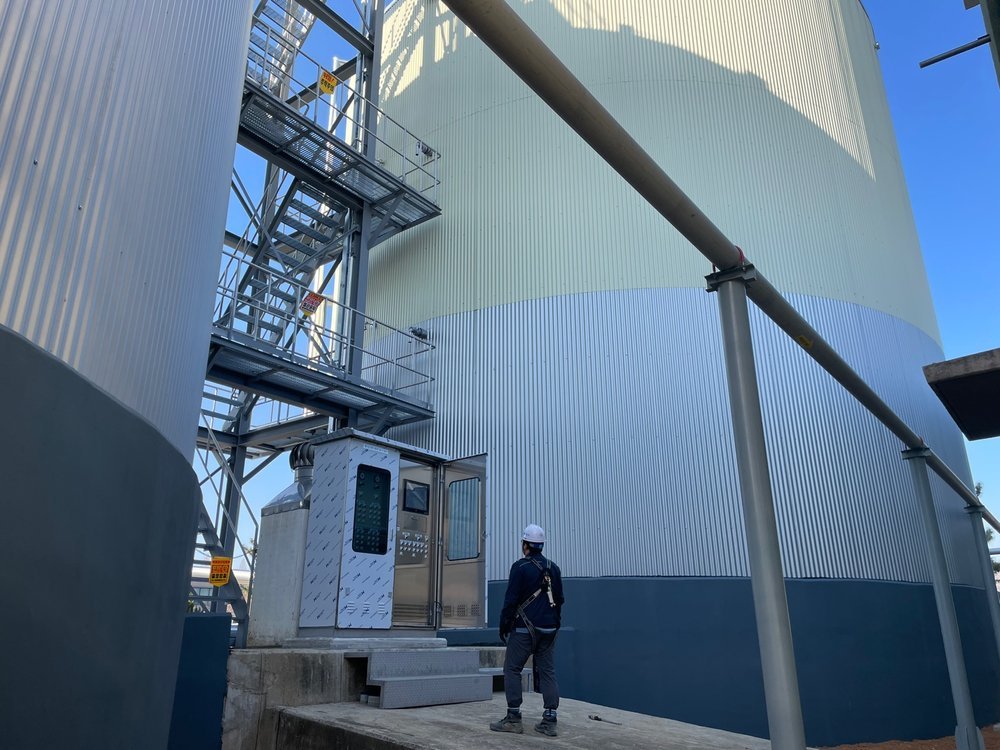

Biogas plant,

verified with various references and patents

- Minimizing digestor volume by treating solids of max 17% concentration

- Improved biogas production with Sequence Batch Reactor(SBR) operation

- Applicable organic wastes

: Food wastes(food wastewater included), livestock manure, sewage sludge, animal/plant wastes

- An established technology to decompose organic matter into methane and carbon dioxide through different steps of hydrolysis, acid fermentation, and methane fermentation in oxygen-free environment

C6H12O6 → 3CH4 + 3CO2- Energy input is low because there is no oxygen supply, and sludge generation is low because anaerobic microorganisms with a slow growth rate are used

- AD is implemented for organic waste volume reduction and renewable energy production facilities

Additional Value from Organic Wastes

•Renewable energy(biogas) production by AD / various application of the biogas

•Producing high value materials from the organic wastes

•Contribution to carbon neutrality by utilizing biogas

- Biogas plant for integrated treatment of wastes

- Energy producing plant using organic wastes

- Energy producing process for net-zero wastewater treatment plants

- High Performance Agitator

Enabling to treat high total solids influent, and suppression of upper scum and prevention of lower sediment sedimentation by preventing the occurrence of dead space in the digester

- Solids Discharge System

Reducing dead zone and preventing sedimentation and adhesion

- Cultivation of Dense Microorganisms

Adjustable to fluctuation

- Better Digesting Efficiency

Secured retention time leading to improved gas production and stable volatile solids(VS) removal

Maximizing stability and efficiency

Operating as Anaerobic Sequence Batch Reactor(SBR)

- Dense anaerobic microorganisms cultivation corresponding to fluctuation

- Intermittent agitation for saving operation cost

- Long SRT compared to HRT, resulting in improved biogas production

* HRT (Hydraulic Retention Time) * SRT (Solid Retention Time)

Operation data from Miryang Biogas Plant

간편한 분석의 진단을 통한 이게 해외도 가능함? 확인 후 번역 or 삭제

비상 시 선제적 대응 가능

- 기존 진단 기술의 현장 적용 어려움 해결

- 밀폐 구조 소화조로 인해 상태 진단 어려움 해결

- 계측 설비(pH, 온도, 가스 유량계 등) 대비 이상상태 조기 발견

- 간단한 분석을 통한 소화조 상태 진단, 이를 이용한 선제적 대응

Operation data from BKT’s demo plant

Facility capacity: Total 100 tons/day (livestock manure 80 tons/day, food 20 tons/day)

Methane production rate: 0.40 Nm³ CH₄/kgVS (design)

Organic matter removal rate: 70.0% (design)